3 tips for laundry plant setup temperature management

During the summer peak season, in addition to the peak of laundry business, the high temperature in the laundry plant setup of the laundry plant setup brings about the loss of employees and the risk of thermoplegia, causing the entire front-line to enter the most difficult state. The owner of a laundry business feels sad every summer, and the high temperature in the workshop will definitely become the focus during the summer, and it is a hot topic that the industry pays more attention to.

Why can’t the high temperature of the laundry plant setup drop?

This is a topic worthy of deep consideration!

The phenomenon of high temperature in the laundry plant setup in summer is actually quite complicated. It is not only necessary to consider the measures for the controllable temperature from the stage of planning and designing; After completion, take scientific and reasonable cooling measures.

In particular, many laundry plant setup, on the one hand, hardly do any insulation, but at the same time spend a lot of money on cooling. This approach is like throwing money into the water very hard, but they don’t know it. In order to let more laundry business factories avoid these unnecessary waste and losses, this article is specially written to discuss with you.

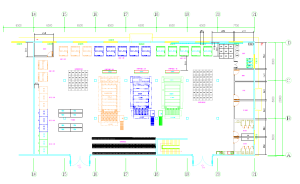

1. Planning considerations for workshop temperature planning

For a new laundry plant setup, during the planning period, it is necessary to set corresponding requirements for the temperature of the future workshop. It is generally recommended that the temperature in the laundry plant setup can be controlled to be about 5°C lower than the outdoor temperature under the premise of the highest temperature, and a certain wind speed should be provided, so that people in the workshop will feel comfortable.

Effects of workplace air freshness on human perception. Freshness refers to harmful gases and odors, carbon dioxide concentration and air negative ion concentration in the air. If the concentration of the first three is too high, it will make people feel uncomfortable and nauseated.

They should be discharged in time and fresh air should be added. The main sign of air freshness is negatively charged air ions, i.e. negative air ions. Practice has shown that people who work in an environment with few negative air ions generally suffer from dizziness, headache, fatigue, chest tightness, elevated blood pressure, and anxiety and are prone to illness.

The main method of artificially producing negative air ions is to use the spraying effect of pressure water to make water droplets form negative air ions when they split.

It is suggested that the measures that can be considered in the planning and design stage are the insulation measures for the roof and walls of the workshop. The insulation effect of the brick-concrete factory building must be much better than that of the steel structure.

If the steel structure can adopt high-efficiency energy-saving walls, thermal insulation, heat insulation, and sound insulation measures, it can reach 50% energy-saving standards. In particular, thermal insulation and ventilation measures are taken on the roof, which can form a flowing air space above the interior of the house to meet the ventilation and heat dissipation needs of the roof.

In order to ensure the thermal insulation effect of the steel structure, thermal insulation materials are used in the outer wall and roof of the building.

In addition to filling the glass fiber between the wall columns, a layer of thermal insulation material is pasted on the outside of the wall to effectively isolate the Through the thermal bridge between the wall column and the outer wall panel; the glass fiber is filled in the joist between the floors to reduce the heat transfer through the floor, which will ensure the insulation effect of the steel structure.

2. Equipment and facilities are installed with insulation measures in place

The equipment and facilities of the laundry plant setup, as well as the related steam pipes and valves, do not have standard insulation measures, which will cause a large amount of heat to be emitted during the production process, especially the flatwork roller ironing machine, resulting in the ambient temperature of the entire workshop. keep rising.

Even if the steam pipes in many washing factories are insulated, when the author asked how to confirm the insulation effect of the steam pipes during the investigation of a large number of washing factories, few washing companies could answer accurately, that is to say, even if the pipes are insulated, many times Not necessarily effective.

Generally, a temperature measuring gun is used to detect the insulation layer of the pipeline. If the surface temperature exceeds 50°C, it basically indicates that the insulation effect of the pipeline is not up to standard. In addition, the insulation of many valves is hardly done, which is also an aspect of the heat source being out of control.

In the washing equipment, the most important thing is the heat dissipation and heat preservation measures of the ironing machine. Even though many washing companies have made heat-insulated exhaust hoods, unfortunately, most of the materials selected for the heat-insulated exhaust hoods will be metal plates with high thermal conductivity, the effect of this kind of heat insulation and ventilation is very bad.

It is recommended to replace it with a material with a lower thermal conductivity. Calcium silicate board can be considered. The thermal insulation effect is better, the cost of calcium silicate board is low, and the installation is relatively simple.

At the top; if it is a steel structure factory building, you can consider installing an exhaust pipe. Considering that the environment inside the heat shield is high temperature and high humidity, it will reduce the effect of scalding. It is necessary to set the air inlet as a grille and install a suitable exhaust Tubes and fans.

All equipment, facilities and pipeline valves need to have appropriate thermal insulation measures, so that cutting off the continuous heat source from the source is an important prerequisite for cooling the laundry plant setup.

3. Scientific and reasonable cooling measures

Many Laundry business factories take some different cooling measures every year, and they always feel that the effect is not ideal. The reason lies in the problem of the airtight laundry factory.

Landry factories need to have a large amount of goods in and out every day, resulting in many washing factories basically having two doors that are open, and it is difficult to be airtight.

Once the two doors are always open, there will be continuous heat entering, which will bring about unsatisfactory cooling effects. Especially in washing factories with water curtain cooling measures, this problem will be more prominent. In the process of market visits, the author will see that some washing factories have been able to solve this problem very well.

They have adopted induction automatic rolling doors, which not only meet the needs of airtight heat insulation, but also meet the requirements of goods in and out. Through this detail, it is enough to explain that scientific and reasonable cooling measures still need to return to basic common sense and principles.

In short, the high temperature response in the laundry plant setup can reflect the systematic ability of the laundry factory management, as well as the ability to apply professional knowledge, believe in the power of knowledge, believe in the value of professionalism, and make a temperature control plan in advance, which makes every year a headache.

The high temperature in the workshop is completely solved, and it is worth every washing company to take it seriously!